TEDOM globally

EXPERIENCE

OF TEDOM

COUNTRIES

BRANCHES

Milestones of Our Development

Milestones of Our Development

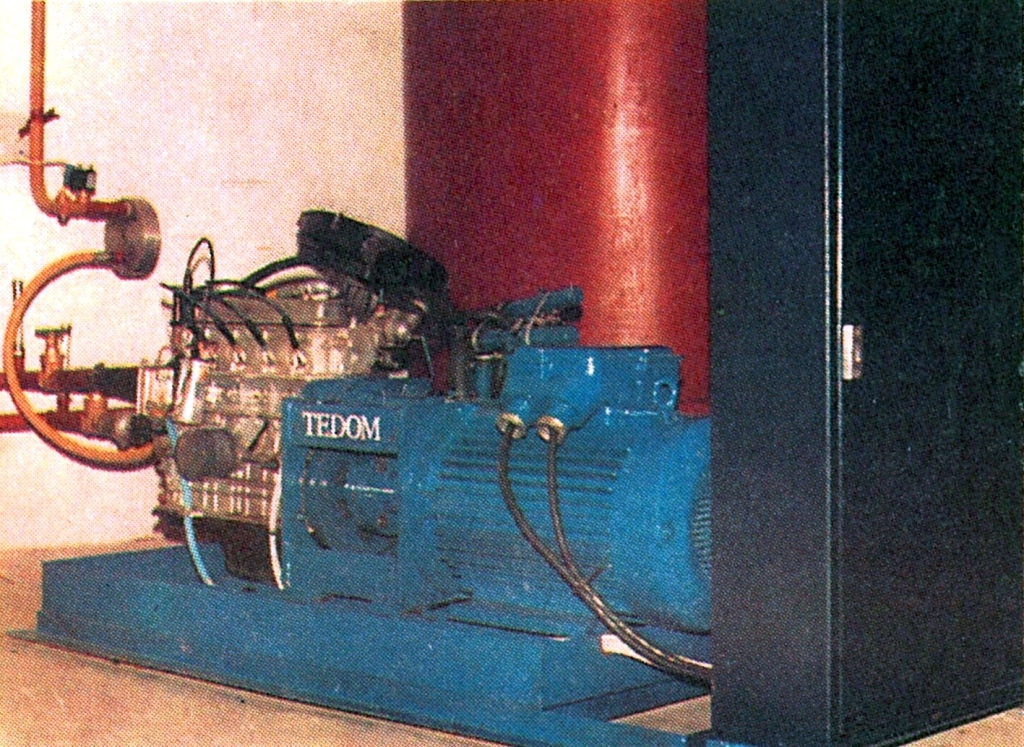

The business begins: The first TEDOM CHP unit with an output of 22 kW and an engine from Škoda Favorit heats up a family house in Výčapy and lives up to its name – that is because TEDOM stands for TEplo DOMova, which means the warmth of home in Czech.

We begin our partnership with VKS s.r.o. in Hořovice, which becomes a manufacturer of the mechanical components of CHP units.

In order to use the LIAZ diesel engine in CHP units, we convert it to a gas engine.

The companies TEDOM and VKS connect their capital. The number of manufactured CHP units reaches 100 pieces.

CHP units with American Caterpillar engines are launched.

We begin the production of new units with 22 kW output called Premi.

In Riga, Latvia an energy centre for the use of landfill gas is build.

The 1000th TEDOM CHP unit is manufactured. We buy the LIAZ engine plant, thus gaining our own engines for the Cento series CHP units.

In Třebíč, we open a new assembly plant for production of TEDOM city buses with gas engines.

The number of manufactured CHP units reaches 2000. In the territory of Ostrava-Karviná, the 2nd stage of the landfill gas energy utilization project is completed.

In order to operate cogeneration energy sources, we create a daughter company called ČEZ Energo in collaboration with ČEZ a.s.

We start building an energy centre at the airport in Sydney, Australia. The production of buses is terminated, and the production of Micro and Cento units is moved from Hořovice to Třebíč.

CHP units with Swiss Liebherr engines are added to the Cento series. At the end of the year, we introduce a new prototype of TEDOM Polo 100 gas heat pump.

We rank 55th in the annual competition of companies Czech Top 100.

In October 2016, we acquire SCHNELL Motoren, a significant German manufacturer of biogas CHP units, thus gaining additional production and development facilities as well as an extensive service network in Germany.

Jet Investment acquires a majority share in TEDOM a.s. through the Jet2 investment fund.

The offer of CHP units is expanded with the new FLEXI series.

Vladimír Hlavina is appointed the new CEO of TEDOM a.s.

We are expanding our portfolio and starting to offer our customers comprehensive energy services: installation of photovoltaic power plants, support services for ČEPS, design, construction, and operation of energy sources.

TEDOM is undergoing a complete rebranding, which, in addition to a logo redesign, includes an overall change in brand perception to a company providing broader energy services.

Japanese engineering and energy company YANMAR acquires a majority share in TEDOM a.s.

Innovation and development

of Landfill Gas

As early as 1993, we began to cooperate with the LIAZ engine plant in Jablonec nad Nisou to modify the original diesel engines to gas-ignition engines for use in cogeneration units. This modification meant the development of new cylinders, modification of cylinder heads to accommodate spark plugs instead of injectors and many other things. The engine developed became the basis for our most successful Cento series units.

After the acquisition of the Jablonec engine plant in 2003, we completed the development of an electronically controlled engine for the combustion of compressed natural gas. This engine is particularly suitable for transport vehicles such as buses, trucks or rail cars.

In 2004, we introduced a prototype of our own low-floor bus powered by compressed natural gas. In 2007, we began mass production of these vehicles, but discontinued this in 2011 and focused all our efforts on further development of CHP units.

We operate 22 energy sources at 16 waste landfills in the Czech Republic. This enables us to produce over 42,000 MWh of “green electricity” annually, reducing CO2 emissions by more than 45,000 tons compared to conventional electricity production methods in the Czech Republic.

Flexibility aggregation allows adjusting electricity production to match fluctuations in the supply of electricity from renewable sources. While electricity production recently adapted to consumption patterns, the future model will reverse, with consumption adjusting to production. This may involve shifting electricity consumption to times when more renewable energy is available or utilizing storage, such as batteries in electric vehicles, to store energy from renewable sources for later use.

As early as 1993, we began to cooperate with the LIAZ engine plant in Jablonec nad Nisou to modify the original diesel engines to gas-ignition engines for use in cogeneration units. This modification meant the development of new cylinders, modification of cylinder heads to accommodate spark plugs instead of injectors and many other things. The engine developed became the basis for our most successful Cento series units.

After the acquisition of the Jablonec engine plant in 2003, we completed the development of an electronically controlled engine for the combustion of compressed natural gas. This engine is particularly suitable for transport vehicles such as buses, trucks or rail cars.

In 2004, we introduced a prototype of our own low-floor bus powered by compressed natural gas. In 2007, we began mass production of these vehicles, but discontinued this in 2011 and focused all our efforts on further development of CHP units.

of Landfill Gas

We operate 22 energy sources at 16 waste landfills in the Czech Republic. This enables us to produce over 42,000 MWh of “green electricity” annually, reducing CO2 emissions by more than 45,000 tons compared to conventional electricity production methods in the Czech Republic.

Flexibility aggregation allows adjusting electricity production to match fluctuations in the supply of electricity from renewable sources. While electricity production recently adapted to consumption patterns, the future model will reverse, with consumption adjusting to production. This may involve shifting electricity consumption to times when more renewable energy is available or utilizing storage, such as batteries in electric vehicles, to store energy from renewable sources for later use.